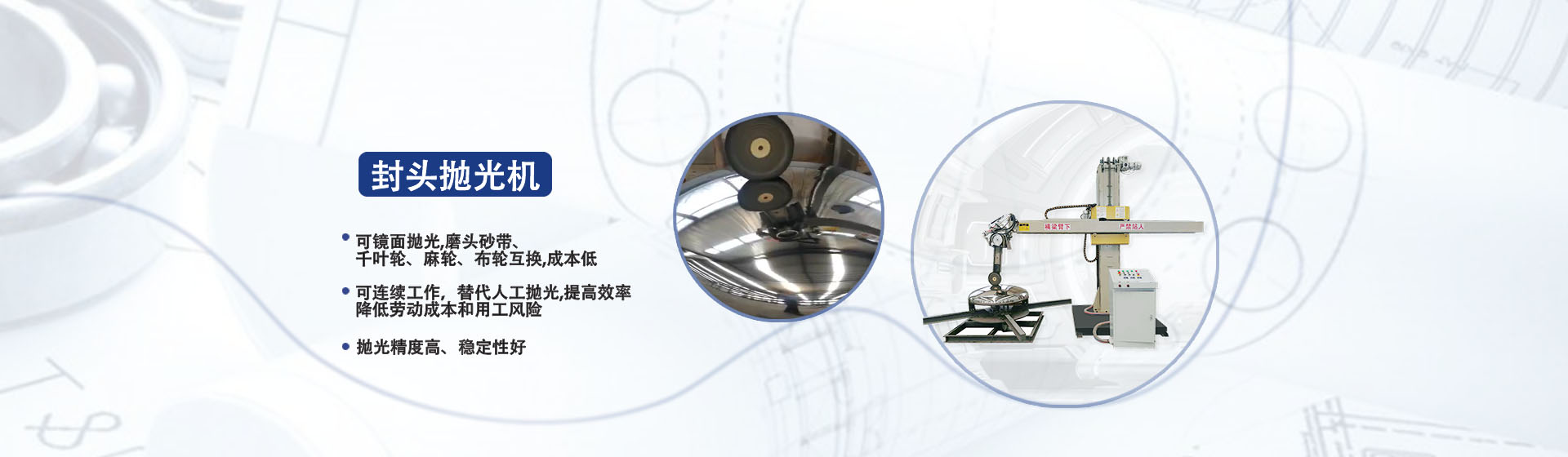

Transportation manufacturers seek the highest caliber of precision in parts. A critical aspect is achieving a exquisite polishing on sunken sections, which can be difficult with traditional systems. Our cutting-edge Precision Dished EndAC Polishing Machine fulfills this requirement by presenting an self-regulating and precise answer. This equipment applies tailored tooling and a controlled polishing approach to obtain a sleek appearance on indented closures, assuring optimal capability and durability of automotive modules.

- The contraption’s programmable settings facilitate for precise alterations to the polishing standards, ensuring steadiness and consistency.

- Its streamlined design improves workspace capacity while limiting operator tiredness.

- Merging with existing manufacturing systems is simple, enhancing production lines.

Advanced Tank Polishing Machines for Stainless Steel Fabrication

In the sphere of stainless steel assembly, reaching a exquisite and shiny finish is indispensable. To realize this feat, high-efficiency tank polishing machines have come forth as necessary devices. These high-tech machines adopt cutting-edge technology to rapidly excise surface blemishes and impart a sparkling sheen on stainless steel tanks.

- In addition, high-efficiency tank polishing machines are built for optimal performance, providing durable construction, strong motors, and modern polishing heads that lower surface damage.

- Therefore, fabricators can secure exceptional results with minimal effort, refining their production processes and ensuring high-quality tanks that conform to the stringent requirements of various areas.

Advanced Cylindrical Polishing System for Precision Engineering

The request for exceptional surface finish in precision engineering is constantly spreading. To address these rigorous prerequisites, a fresh cylindrical polishing system has been created. This cutting-edge apparatus harnesses cutting-edge mechanisms to secure unparalleled surface evenness. It powerfully eradicates imperfections and strengthens the overall performance of cylindrical parts across a wide range of areas.

- Benefits include increased performance, reduced manufacturing expenses, and improved product trustworthiness.

- The system is designed to handle a broad range of products, including metals, ceramics, and plastics.

- Professionals can easily adapt the polishing parameters to achieve the desired sheen.

This advanced cylindrical polishing system represents a significant milestone in precision engineering, helping manufacturers to produce sections of exceptional grade and efficiency.

State-of-the-art CNC Polishing Solutions for Complex Shapes

Securing a unblemished texture on intricate elements can be a complicated task. Traditional polishing systems often struggle to provide consistent results on complex profiles, bringing about time-consuming rounds. However, the advent of computerized CNC polishing solutions has upgraded the industry, supporting manufacturers to achieve unprecedented grades of accuracy and efficiency.

These advanced systems exploit smart machining technology to carefully buff surfaces with minimal operator intervention. Equipped with fast spindles and a variety of polishing tools, CNC machines can smoothly handle even the most demanding forms.

Additionally, these solutions offer optimized control over settings such as pressure, speed, and tool path, ensuring consistent results across different materials and complexities.

- Benefits of automated CNC polishing include:

- Raised precision and surface caliber

- Minimized cycle times and production costs

- Upgraded product consistency and repeatability

- Expanded design flexibility for complex shapes

Rugged Tank Polishing Machine for Industrial Applications

For demanding industrial environments where output is indispensable, a industrial-strength tank polishing machine is an vital tool. These machines are specifically developed to handle the demands of sustained operation in tough environments. Equipped with durable construction and high-torque motors, they can effectively eliminate rust, paint, and several contaminants from tank surfaces, assuring a smooth and sanitary finish. A variety of attachments are available to accommodate different tank sizes and layouts, making them versatile for a wide range of applications.

An Innovative Dished End Polisher Featuring Adaptive Control

Our innovative Dished End Polisher incorporates automated Adaptive Control Technology to deliver unparalleled accuracy. This tool continuously monitors the polishing process in real time, maintaining optimal surface finish for a wide range of components. The Adaptive Control Technology automates the adjustment of key controls, such as pressure, speed, and oscillation, to achieve repeatable results every time.

- Pros include:

- Improved surface finish quality

- Lessened polishing time

- Heightened control over the polishing process

- Customizability for a range of materials and applications

CNC Polishing Machine for Surface Finishing and Refinement

A CNC polishing equipment is a advanced tool utilized in various sectors for realizing distinguished surface finishes. These machines command computer numerical control (CNC) technology to efficiently polish surfaces, extracting imperfections and crafting a smooth, refined appearance. The resilient design of CNC polishing machines grants for small batch runs.

- Fabrication environments

- Non-metals

- Achieving desired textures

The automated nature of CNC polishing machines ensures consistent results, reducing human error and boosting efficiency. By employing a variety of abrasive materials, these machines can process a comprehensive set of surface forms and components.

Precision Equipment for Large Cylinder Polishing

Assembling and refining large diameter cylindrical objects often needs specialized equipment. These machines are designed to secure precise measurements on objects with significant girth, employing a variety of polishing pads.

The choice of cylindrical polishing equipment depends heavily on the specific setting and desired outcome. Some common types include orbital finishing units, each offering distinct advantages for enhancing appearance.

- Positioning tools are essential to securely hold large diameter pieces throughout the polishing process.

- Precise control of rotating speed and abrasive application are critical for producing consistent results.

Ultrafast Dished End Polishing Machine for Mass Production

In modern quickly shifting manufacturing environment, the call for optimized high-volume production procedures is paramount. To meet this demand, manufacturers are embracing cutting-edge technologies like high-speed dished end polishing machines. These innovative apparatuses deliver exceptional correctness in a time-sensitive manner, maintaining consistent quality and top-notch surface finishes for a extensive range of components.

Engineered to handle large production runs with unprecedented speed, these machines use advanced polishing techniques to achieve flawless finish required for demanding applications. Fundamental features include high-speed spindles, intelligent control systems, and innovative polishing pads that work in synergy to maximize results.

Furthermore, these machines often incorporate automation mechanisms for increased yield and reduced labor costs. This combination of speed, accuracy, and mechanization makes high-speed dished end polishing machines a vital asset for manufacturers trying to boost their production processes and satisfy the growing demands of the market.

Pinpoint CNC Polishing for Aerospace and Therapeutic Devices

In the stringent fields of aerospace and medical device construction, surface condition is fundamental. CNC polishing furnishes a highly detail-oriented and secured method to produce the exacting appearances required for these critical applications. By applying advanced CNC machining technology, manufacturers can create surfaces with exceptional gloss, rigor, and sturdiness. This process empowers the production of components that satisfy stringent specifications for output, reliability, and stability.

- demands needs requirements demands tank polishing machine expectations

- As well, CNC polishing elevates the rusting resistance and biocompatibility of items used in aerospace and medical devices.

- Accordingly, it plays a vital role in extending the lifespan and enhancing the effectiveness of these products.

Modular Cylindrical Polishing System for Customization

Revealing a revolutionary strategy to cylindrical polishing: the Modular Cylindrical Polishing System. This innovative system grants unparalleled customization, modifying to your specific conditions. With its scalable design, you can seamlessly adjust the polishing heads, parts, and parameters to deliver the precise finish for your cylindrical objects.

- preferences needs demands

- Feature1

- Benefit2

- Strength3