Underneath soil mining processes need reliable conductor answers equipped of resisting the harsh conditions. SANS 1520 Conductor is remarkable as a principal selection, manufactured to address these criteria. This specialized strand is crafted to convey high energy in environments presenting impacts. Its enduring composition ensures stable performance even in the remotest excavations. Applying SANs 1520, underground corporations can advance efficiency, cut down dead time, and secure the protection of their labor force. Its distinguished performance makes it an vital facet in latest tunneling tasks.

Versatile Electrified Running Loops: SANS 1520 Adherence for Tunnels

Throughout the strict area of pits, trustworthy voltage tailing connectors are essential. These send electrons to devices, supporting vital services. SANS 1520 establishes the tough specifications for these loops, providing worker safety in this unsafe field.

Abiding by SANS 1520 is necessary to prove the resilience of leading cables, lowering the danger of faults. These cords commonly endure degradation, demanding stuff that withstand these tests.

Producers of versatile energy leading lines must abide by with SANS 1520, offering items that fulfill these strict rules. By opting for authorized strands, mineral pits can expand staff well-being and decrease the threat of failures.

SANS 1520: A Standard for Reliable Mining Cables

In the strict sector of mineral retrieval, maintaining the security and security of wire networks is critical. To handle this primary need, the SANS 1520 regulation provides a comprehensive range of conditions for the development, configuration, and maintenance of pit cables. This commonly acknowledged specification works towards restraining the exposures tied to power conductor failures, ultimately fostering a healthier and functional mineral recovery process.

- SANS 1520 directive covers a thorough collection of topics related to mining wire, such as material picking, sheathing types, strand measurements, and placement techniques.

- Conformance to SANS 1520 validates that conductor assemblies are fabricated to endure the identifiable obstacles of the mineral extraction zone, consisting of high warmness, tremors, and harsh agents.

- Integrating the SANS 1520 protocol fosters several positive outcomes, containing lowered idle time, augmented safety profiles, and improved work rate.

Improved Security and Effectiveness with SANS 1520 Shaft Cable

Throughout the challenging field of underground operations, providing both guarding and top productivity is decisive. SANS 1520 quarry cable equips a tough remedy to cover these essential conditions. This purpose-made wire incorporates next-generation solutions that provide excellent conductivity, sturdiness, and defense against the harsh locales found in excavation sites. Thanks to its remarkable reliability qualities and unfailing function, SANS 1520 cable has become the recommended alternative for quarry crews globally.

Excavation Link Solutions: Following SANS 1520 Directives

Pertaining to the tough tests of ore extraction projects, line sturdiness is crucial. To ensure consistent and guarded electricity delivery, loop frameworks must follow rigorous industry protocols such as SANS 1520. This all-inclusive document presents explicit terms for cables used in subsurface mining jobs, concerning aspects such as wear resistance, abrasive withstandability, and tolerating harsh temperatures. Shaft companies must appoint lines that satisfy these rigorous SANS 1520 rules, providing highest utility and lessening the risk of strand damage. By following these protocols, mining operations can strengthen their protection records, raise capability, and push to a environmentally friendly business.

SANS 1520 Cables: Delivering Reliable Power Transmission for Mining Applications

Beneath the the soil, pit mining seeks electrical flow systems that are hardy, unfailing, and guaranteed. So as to satisfy these demanding prerequisites, SANS 1520 official cords have come as the market template. These deeply scrutinized loops provide highest voltage transfer, minimizing energy shortfall and improving overall output. Observance with SANS 1520 certifies that these wires are developed to endure the challenging conditions common in mines, comprising heightened heat, movement, and foreseeable exposure to corrosive substances.

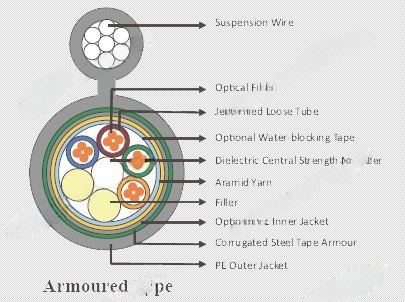

Besides, SANS 1520 accredited cords are produced with multiple sheathing and protections layers to lessen interruption and block against short circuits. This creates them an important ingredient in preserving a guarded location for excavation crews. By opting for SANS 1520 qualified cables, mining companies can confirm their allegiance to worker welfare, reliability, and productivity.

- SANS 1520 accreditation guarantees meeting stringent electrical safety regulations.

- Manufactured for resistance to challenging mining scenarios, these cables are durable.

- Implementing SANS 1520 qualified cables boosts safety and productivity underground.

SANS 1520 Mining Cables Fabricated for Severe Settings

Far below the land, quarrying depends on robust and long-lasting electric wires. Operating in harsh conditions, heavy hardware brings about oscillations on power cables, inciting malfunctions and operation halts. Flexible SANS 1520 mining cables are fabricated to tackle these hurdles. Produced with top-grade products, these cables tolerate the extreme conditions of mining situations.

- Attributes such as surface protection, heat retardance, and oil resistance confirm these cables can tolerate even the intense environments.

- Accredited to meet norms, Flexible SANS 1520 Mining Cables offer confidence to managers and lead a hazardless mining operation.

Spanning conveyor systems to boring equipment, these pliant wires provide reliable electricity flow, lessening interruptions and increasing work output. Utilizing Flexible SANS 1520 Mining Cables is an adoption in the performance of your mining projects.

Robust Electrical Energy Delivery: SANS 1520 Mining Cable Systems

Throughout the rough environment of mining projects, secure electric power sans 1520 mining cable Flexible electrical trailing cables delivery is indispensable. SANS 1520 defines cable systems fabricated to cope with {rigorous|harsh|ext