Within the universe of industrial activities, preserving the integrity and efficiency of pipelines is paramount. Buildup of impurities within ducts can substantially thwart stream velocity, undermine yield grade, and elevate maintenance costs. To confront these hurdles, channel scrubbing procedures have developed as remarkably potent cures for smooth pipeline sanitation. A contraption, commonly a barrel-shaped implement, is pushed through the pipe, productively cleaning dirt and ensuring ultimate output

Tube sanitation mechanisms furnish diverse merits. They are flexible, fit for sterilizing lines of mixed thicknesses and ingredients. Furthermore, they are efficient, performing the cleaning process in a fairly fast timespan. By trimming downtime and enriching pipeline efficiency, pipeline cleaning systems support cost reductions and boosted operational output

Health-Driven Pipe Systems:

Protecting pipeline purity is paramount for confirming yield protection and excellence of relayed outputs. Sanitary pigging systems supply a steady way to accomplish this target. Pigs, specialized contraptions, are deployed into pipelines to purify by clearing residues and pollutants

- Multiple categories of sanitary pigs are found, each created for special cleaning functions.

- These pigs are created from substances that follow stringent safe standards.

- Regular sanitary pigging actions enable curtailing product pollution, lengthen pipeline service life, and augment complete performance.

Modern Pigging Techniques for Top Operation

pigging systemsWithin the area of tubing preservation, innovative pigging techniques have surfaced as a major instrument for guaranteeing peak output and safeguarding. These frontline systems utilize ingenious structures and features to efficiently purge, examine, and defend pipes from degradation. From cognitive pigs loaded with instantaneous surveillance capabilities to dedicated pigging tools meant for careful tasks, growth in this subject is uninterruptedly surpassing limits. By exploiting these enhancements, controllers can notably increase pipeline soundness, minimize downtime, and enhance operational functionality.

Broad Pigging Setup Development and Installation

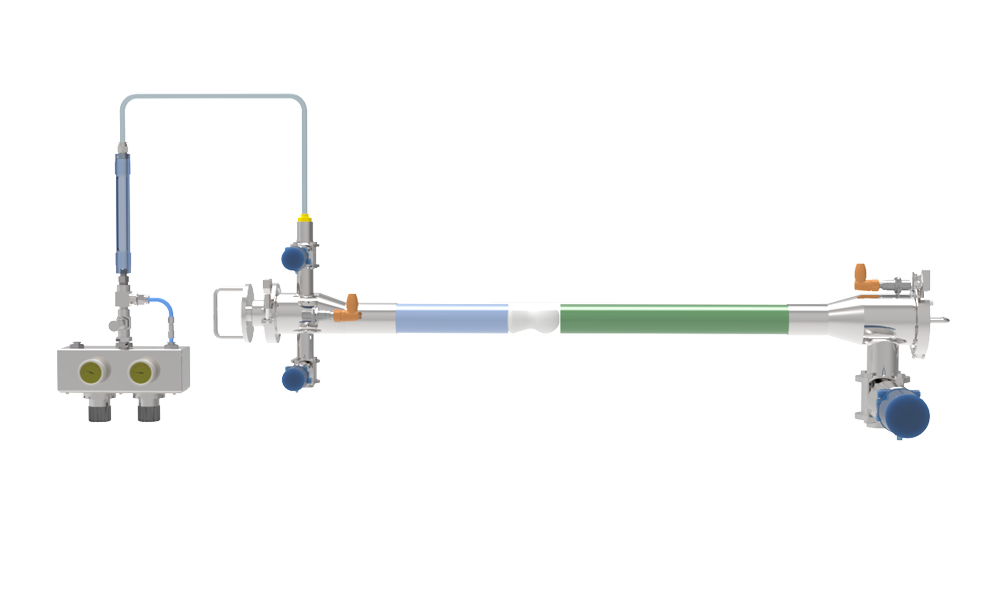

A full-scale pigging system incorporates a key strategy for pipeline maintenance. This routine consists of the installation of custom devices called pigs, which venture through pipes to sanitize, analyze, and defend their stability. The design puts weight on components such as conduit extent, content, pig class, and operational specs. A intelligently crafted system delivers effective pigging functions while reducing downtime and potential damages. Installation rules require careful designing, skilled specialists, and strict adherence to safety guidelines to confirm a safe and fruitful product

Mechanical Pigging Instruments for Broad Employments

Commercial pigging instruments are vital means employed across a considerable variety of industries. These equipment promote stable and efficient purging, examination, and management of conduits and other pipe-shaped constructions. Pigging incorporates driving constructed apparatuses known as pigs through pipes to perform numerous jobs. Popular types of industrial pigging apparatus include cleaning pigs, inspection pigs, and transfer pigs. Cleaning pigs are crafted to clear debris, build-up, and fouling from pipelines. Inspection pigs are provided with apparatus that harvest information about the status of pipe bases. Transport pigs are utilized to transport products through pipelines. The use of industrial pigging products provides numerous pros, such as lowered downtime, reinforced pipeline integrity, and amplified operational functionality. These products are regularly employed in realms such as oil and gas, water treatment, chemical production, and food manufacturing.Complete Overview of Pipeline Pigging

Pipeline pigging is an principal protocol used within the oil and gas sector to clean pipelines. This important undertaking embraces deploying custom instruments, termed pigs, into the line. Pigs are crafted to advance through the length of the pipeline, performing various functions.

Several classes of pigs are at disposal, each customized for a separate target. Common utilizations of pipeline pigging invoke surveying for defects, cleaning, and protective layer application.

- Advantages of Pipeline Pigging

- Influences on Operational Efficiency

- Groups of Pipeline Pigs

Proven Sanitation with Pigging Solutions

Pigging processes offer a reliable answer for maintaining sanitation inside conduits. These methods utilize specially designed pigs that operate through the pipeline network, quickly extracting contaminants. The approach is especially valuable for areas that require rigorous sanitation benchmarks. Pigging technologies grant a affordable and timely approach for cleaning passages, lowering the threat of cross-contamination.

Choosing Pigging Hardware for Custom Specifications

Pigging devices serves a significant role in competent pipeline performance. When selecting pigging gear, it is mandatory to consider the unique needs of your purpose. This comprises evaluating details such as pipeline thickness, flow velocity, product category, and management specifications.

Plenty of pigging types are offered, each developed for distinct reasons. For instance, some pigs are built for surveillance, while others are deployed for removing impurities or isolating product collections.

Also, pigging equipment ingredients should be suitable with the delivered material.

It is usually advisable to consult a advisor in pigging technology to validate that you choose the most ideal equipment for your customized requirements.

Systematic Pipeline Cleansing - A Value-Adding Approach

Flow line pigging present a comprehensive array of merits for industries utilizing passages. By efficiently disinfecting and checking duct internals, pigging systems promote operational effectiveness and diminish maintenance expenditures.

A leading pro of pigging systems is their capacity to extract contaminants such as scale, debris, and rusts. This frequent purging helps maintain continuous pipeline stream and curtails costly downtime.

Moreover, pigging systems can be implemented to examine the state of pipelines, discovering possible flaws before they develop into severe challenges. This forward-looking procedure boosts to extend the lifespan of pipelines and minimize overall maintenance costs.

Preserving Hygiene in Pigging Activities

Sow farming practices substantially lean on appropriate hygiene regulations to diminish the passage of illness. Adhering to rigorous hygiene standards maintains a nutritious surroundings for pigs, so that yields optimal health outcomes and production.

Routine cleaning and disinfection of quarters is fundamental to block the spread of harmful bacteria. Proper manure management also plays a key part in preserving hygiene.

Furthermore, {workers