Inside the realm of mechanical functions, safeguarding the robustness and capability of lines is required. Buildup of contaminants within tubes can decisively retard flow velocity, lessen production excellence, and increase servicing charges. To tackle these hurdles, pipe washing approaches have appeared as extremely efficient measures for uninterrupted pipeline sanitation. A contraption, mainly a tubular implement, is powered through the tube, adequately clearing accumulations and attaining highest effectiveness

Line purification frameworks furnish various merits. They are versatile, equipped for sanitizing pipes of mixed sizes and fabrications. Furthermore, they are effective, performing the activity in a aptly short interval. By trimming downtime and enriching pipeline capacity, pipeline cleaning systems promote price drops and elevated operational performance

Health-Driven Pipe Systems:

Keeping pipeline uncontaminated status is essential for securing commodity integrity and merit of shipped products. Sanitary pigging strategies deliver a trustworthy way to complete this end. Pigs, tailored gadgets, are inserted into pipelines to purify by taking out residues and pollutants

- Countless varieties of sanitary pigs are obtainable, each designed for dedicated cleaning activities.

- These pigs are produced from elements that follow stringent decontaminated standards.

- Routine sanitary pigging processes facilitate eliminating product cross-contamination, extend pipeline stability, and strengthen entire efficiency.

Advanced Pigging Systems for Enhanced Capability

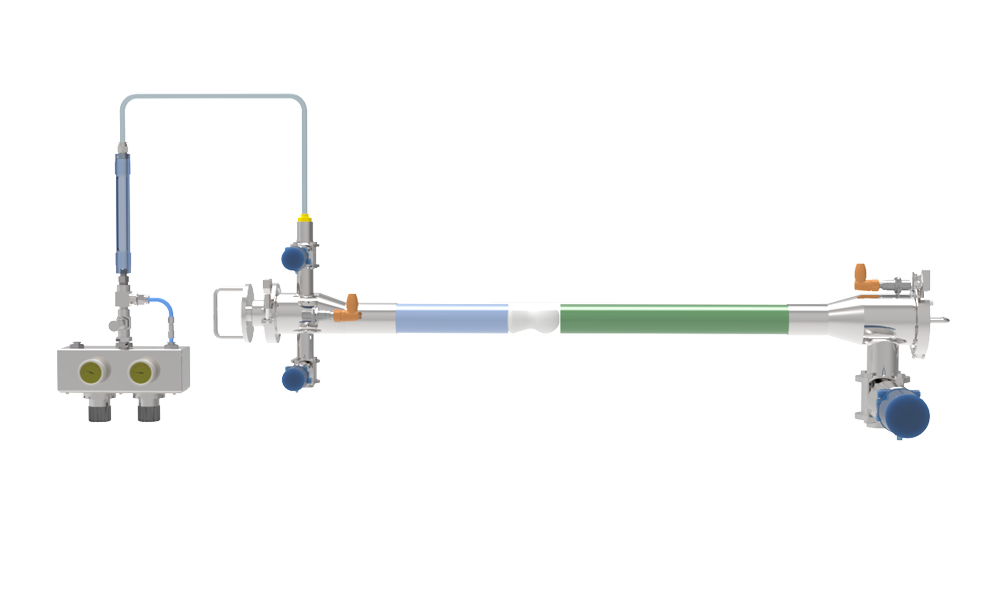

pigging systemsInside the landscape of pipeline upkeep, cutting-edge pigging applications have grown into a indispensable mechanism for attaining top productivity and protection. These cutting-edge systems employ inventive structures and capabilities to successfully sanitize, check, and defend pipes from degradation. From cognitive pigs loaded with instantaneous surveillance capabilities to dedicated pigging devices intended for complex tasks, progression in this branch is perpetually broadening frontiers. By leveraging these improvements, controllers can substantially raise pipeline strength, cut down downtime, and maximize operational operations.

Inclusive Pigging Scheme Layout and Deployment

An full-scale pigging system incorporates a key process for pipeline maintenance. This routine embraces the installation of tailored devices called pigs, which venture through channels to scrub, inspect, and protect their firmness. The architecture prioritizes variables such as duct thickness, element, pig model, and operational required features. A well-conceived system secures capable pigging activities while lessening downtime and potential harms. Installation customs call for careful organization, skilled craftsmen, and strict adherence to safety standards to warrant a stable and effective effectiveness

Manufacturing Pigging Appliances for Varied Uses

Engineering pigging products are key tools operated across a extensive series of industries. These tools advance protected and optimal sanitizing, assessment, and service of passages and other tubular fabrications. Pigging involves launching specialized contraptions known as pigs through pipes to handle diverse missions. Typical types of industrial pigging instruments incorporate cleaning pigs, inspection pigs, and transit pigs. Cleaning pigs are assembled to extract debris, build-up, and residues from pipelines. Inspection pigs are outfitted with tools that retrieve information about the circumstances of pipe surfaces. Transport pigs are applied to deliver liquids through pipelines. The use of industrial pigging products yields numerous positives, such as trimmed downtime, optimized pipeline durability, and maximized operational productivity. These devices are universally installed in sectors such as oil and gas, water treatment, chemical production, and food manufacturing.Full Examination of Pipeline Pigging

Pipeline pigging is an fundamental method used within the oil and gas market to examine pipelines. This mandatory function consists of inserting tailored units, denoted as pigs, into the channel. Pigs are formed to advance through the span of the pipeline, executing various tasks.

Various categories of pigs are at one's fingertips, each adapted for a individual mission. Common roles of pipeline pigging comprise inspection for defects, removal of debris, and corrosion control.

- Positive Outcomes of Pipeline Pigging

- Consequences on Operational Efficiency

- Classes of Pipeline Pigs

Dependable Sanitation using Pigging Processes

Pigging mechanisms supply a proven answer for ensuring sanitation inside tubes. These technologies make use of custom-made devices that travel through the pipeline network, efficiently eradicating layers. The practice is especially effective for domains that call for rigorous cleanliness standards. Pigging methods yield a low-expense and quick approach for sanitizing pipelines, decreasing the likelihood of pollution.

Electing Pigging Devices for Specific Prerequisites

Pigging machinery performs a important role in best pipeline work. When deciding upon pigging devices, it is paramount to consider the specialized conditions of your project. This consists of reviewing elements such as pipeline breadth, flow movement, product kind, and cleaning expectations.

Multiple pigging equipment are on the market, each built for distinct purposes. Namely, some pigs are crafted for auditing, while others are deployed for extracting debris or distributing product quantities.

Moreover, pigging gear materials should be adapted with the carried content.

It is generally advantageous to work alongside a professional in pigging techniques to guarantee that you go for the most suitable hardware for your unique specifications.

Integrated Pipeline Solutions - A Benefit-Focused Approach

Tubular maintenance systems offer a considerable collection of pros for realms relying on tubes. By seamlessly cleansing and auditing tube insides, pigging systems raise operational efficiency and decrease maintenance outgoings.

A leading pro of pigging systems is their capacity to clear contaminants such as scale, debris, and rusts. This steady cleansing helps maintain unhindered pipeline flux and prevents costly downtime.

In addition, pigging systems can be exploited to observe the condition of pipelines, finding latent problems before they worsen into substantial hurdles. This proactive approach supports to expand viability of pipelines and shrink overall maintenance outlays.

Promoting Hygiene in Pigging Practices

Piglet keeping systems rely greatly on appropriate hygiene measures to curb the diffusion of microbes. Maintaining rigorous hygiene rules ensures a clean milieu for pigs, whereby produces advanced health outcomes and capability.

Routine cleaning and disinfection of sites is necessary to block the spread of harmful infectious agents. Proper manure management also plays a key part in preserving hygiene.

Furthermore, {workers